Fara L

Modular plants for pasta making

Pastaria

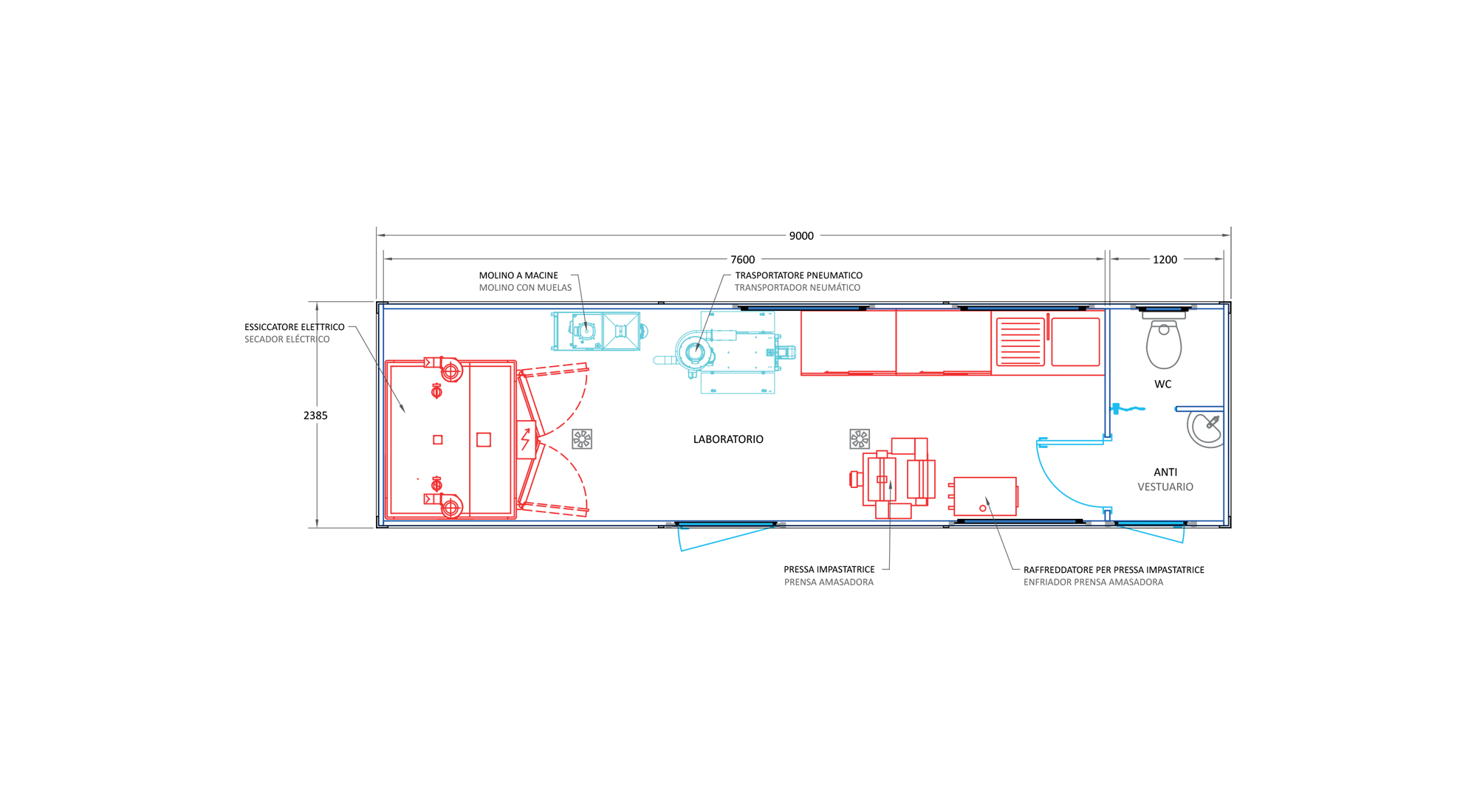

Module from 9 metri

Modular plant prefabricated and ready to use for the pasta production. Built in accordance to the current health and hygiene regulations as well as designed paying particular attention to the spaces optimization.

Our basic standard model offers the possibility of producing fresh and dried pasta from wheat. Our modular plants can be customized with several optional and in accordance to the needs of the customer: it is possible in fact to couple them with other modules or existing buildings in order to increase the storage, the productivity or to diversify the production. Especially appropriate for small companies or individuals who want to enhance their product in a safe and scalable way over time. The many options available for the exterior finishing allow our modular plants to be in compliance with the Environmental Impact Assessment (EIA).

Flexible

Our products are adaptable to any geographical contexts: from plains to urban areas, from mountains to deserts. They are flexible in configuration according with the need of industry as well as thise specific to the customer.

Find out moreModular

The modular structure of our modular plants allows the customer to start their business with a single unit, but with the possibility, in the future, to expand or diversify production, integrating others new structures or expanding those already installed.

Find out moreTechnical drawing

Exterior finishing

Dimensions

| Dim. | Ext. | Int. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Length | 9000 mm | mm | ||||||||

| Width | 2385 mm | mm | ||||||||

| Height | 2995 mm | mm |

Technical features

| Dim. | Int. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Voltage | 400 V – 50 Hz | |||||||||

| Consommation d’électricité | 16 kW est. | |||||||||

| Productivity - Fresh pasta | 60 Kg/h | |||||||||

| Productivity - Dried pasta | from 150 to 300 Kg/day |

Download

To download the document, we kindly ask you to fill in the following form.

At the end of the procedure you will receive a link to download the required data sheet.

Inside equipment

| Dim. | N° | Inc. | Opt. | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dressing room + WC | 1 | ✓ | ||||||||

| Electric water heater 50 l | 1 | ✓ | ||||||||

| Stainless steel table with shelf 1000 x 700 mm | 2 | ✓ | ||||||||

| Cupboard sink 1200 x 700 mm | 1 | ✓ | ||||||||

| Kneading press for pasta | 1 | ✓ | ||||||||

| Cooler for kneading for press | 1 | ✓ | ||||||||

| Electrical dryer | 1 | ✓ | ||||||||

| General electrical panel | 1 | ✓ | ||||||||

| Air conditioning system | ✓ | |||||||||

| Dehumidification system | ✓ | |||||||||

| Grinding mill | ✓ | |||||||||

| Pneumatic conveyor | ✓ | |||||||||

| Sieve | ✓ | |||||||||

| Heat sealer for bags | ✓ |