Roma

Modular plants for fruit and vegetable processing

Fruit & Vegetables

Module from 9 metri

Modular plant prefabricated, multifunctional and ready to use for the production of tomato puree, jams, sauces, paté, ready sauces, fruit juices, sweet or savoury creams, conserves, puree, cooked must, candied products, in oil and pickled products and all those products requiring the phases of scalding, concentration, simple and vacuum cooking, mixing, pasteurization HACCP at 100°C or sterilization at 121°C in autoclave. Built in accordance to the current health and hygiene regulations as well as designed paying particular attention to the spaces optimization.

With our standard models it is possible to process up to around 250 kg/day and they are particularly suited for small and medium sized farms and country houses that want to valorise their own product in a safe and scalable way. Our modular plants can be customized with several optional and in accordance to the needs of the customer: it is possible in fact to couple them with other modules or existing buildings in order to get the health mark CE, to increase the storage, the productivity or to diversify the production. The many options available for the exterior finishing allow our modular plants to be in compliance with the Environmental Impact Assessment (EIA).

Flexible

Our products are adaptable to any geographical contexts: from plains to urban areas, from mountains to deserts. They are flexible in configuration according with the need of industry as well as thise specific to the customer.

Find out moreModular

The modular structure of our modular plants allows the customer to start their business with a single unit, but with the possibility, in the future, to expand or diversify production, integrating others new structures or expanding those already installed.

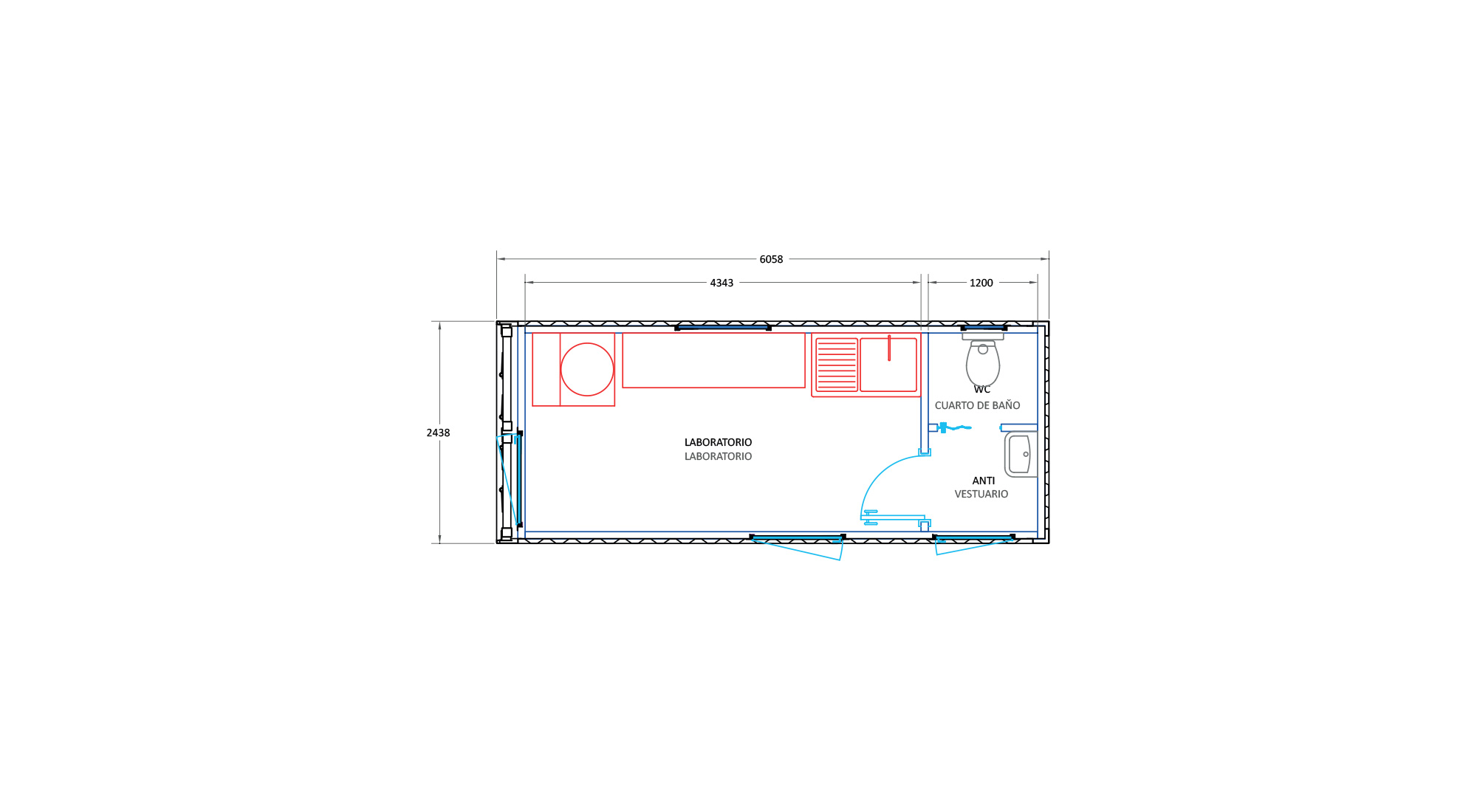

Find out moreTechnical drawing

Exterior finishing

Dimensions

| Dim. | Ext. | Int. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Length | 6058 mm | 5620 mm | ||||||||

| Width | 2438 mm | 2180 mm | ||||||||

| Height | 2896 mm | 2500 mm |

Technical features

| Dim. | Int. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Voltage | 400V – 50 Hz | |||||||||

| Power consumption | 10 kW | |||||||||

| Productivity | 60 - 240 Kg per day* | |||||||||

| Jars 314cc Ø 63 h113 mm | 240 - 1000 per day* | |||||||||

| Bottles 720 ml | 75 – 245 per day/par jour (*) | |||||||||

| Structural optionals - Internal height | 2700 mm | |||||||||

| Certification | ISO |

-

(*) It depends on the type of processing or product

Download

To download the document, we kindly ask you to fill in the following form.

At the end of the procedure you will receive a link to download the required data sheet.

Inside equipment

| Dim. | N° | Inc. | Opt. | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dressing room + WC | 1 | ✓ | ||||||||

| Electric water heater 30 l | 1 | ✓ | ||||||||

| Stainless steel table 2000 x 700 mm | 1 | ✓ | ||||||||

| Industrial dishwasher | ✓ | |||||||||

| Stainl. steel washbasin 1200 x 700 mm | 1 | ✓ | ||||||||

| Electric cooker 30 l | 1 | ✓ | ||||||||

| Electric cooker 50 or 100 l | ✓ | |||||||||

| Pulper 50 Kg/h | 1 | ✓ | ||||||||

| Cart for pulper | ✓ | |||||||||

| Cart with shelves and wheels | ✓ | |||||||||

| Sterilisation autoclave 30 l | ✓ | |||||||||

| Sorting table | ✓ | |||||||||

| Bench pneumatic filler machine | ✓ | |||||||||

| Bench pneumatic capping machine | ✓ | |||||||||

| Patented chill dryer | ✓ | |||||||||

| Extractor of essential oils 100 l | ✓ | |||||||||

| Refrigerated cabinet | ✓ | |||||||||

| Complete washing post | ✓ | |||||||||

| Air conditioning | ✓ |